Exploring the combination of digital fabrication with glass making

Frank Ren

s1942670@ed.ac.uk

In this project, I apply topology optimization and parametric design to explore the possibility of digital fabrication in product design. Then I use 3D printing and some traditional glass techniques to experiment and produce products。

Through the smooth glass surface, we can see the incredible structure brought by the digital design that flies in layers.

Firstly, I built a normal column in rhino and generate a triangle mesh. After that, I set a series of supports and forces with the material I wanted to use in the product developing.

Secondly, I use a plug-in software called Ameba to evolve the model. This app applies topology optimization to generate random structure under the restriction of supporters and forces that users set. However, the result of that is often an imperfect surface with many non-manifold edges, and it took me time to repair the mesh.

Thirdly, I use Meshmixer to further improve the model. I filled holes and polished the objects. I attempted to reduce the number of protrusions and amplitude of protrusions to minimize the amount of supporter used in 3D printing, in order to speed up the printing process.

After I got the 3D printed model, I went to the casting workshop to cast. The process was quite complicated. Simply speaking, the technique takes the advantage of the difference of melting points between plastic, plaster and glass to transform an object from a plastic form to a glass form.

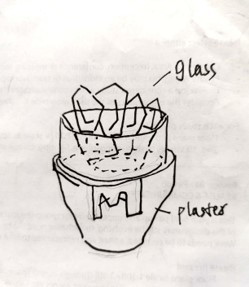

After melting the plastic mould, I cleaned the plaster mould, then placed the prepared funnel and the measured glass together as shown in the diagram and put them in the furnace

Glass moulded after up to a week of firing and cooling. I removed the plaster and cleaned the model.

The most import step was polishing. Glass is very fragile, so I had to be careful.

The final output looks like a crystal!

The glass is delicate but also fragile, it is prone to accidents during the manufacturing process and causes it to be damaged. I was inspired by the traditional Chinese Kintsukuroi process to repair cracks with silver materials.